Best Dust Removal Systems for Woodshops

Woodshops frequently contain woodworking equipment that utilizes abrasive and cutting processes. These processes generate significant amounts of wood dust in a relatively short period of time. Proper ventilation and dust removal is crucial to reducing the possibility of fire hazards, health issues, and housekeeping problems.

Wood Dust Variations

Wood dust can vary greatly based on a number of key variables. These include tree classification (hardwoods vs. softwoods), the presence of other materials (synthetic chemicals used as binders), moisture level of wood, and the machinery or process commonly creating certain sizes of wood dust particles.

The Importance of Dust Removal

Wood dust created from woodworking machinery is combustible. Wood dust has the potential to burn rapidly due to the fine nature of its particles, if an ignition source, oxygen, and fuel (wood dust) are all present at once. Certain wood dusts, including oak and beech, are known to be a carcinogen and a danger to human health. Other wood dusts, such as the western red cedar, can cause increased sensitivity to asthma in human beings. Additionally, when dust is present and loose in the work space, delicate finishing processes such as painting or staining are negatively affected and can result in reduced quality.

The Best Dust Removal for Your Environment

As a result of the inherent hazards present and varying characteristics of wood dust, AGET often recommends specific dust collection system designs to our woodworking customers.

Two-Stage Collection System

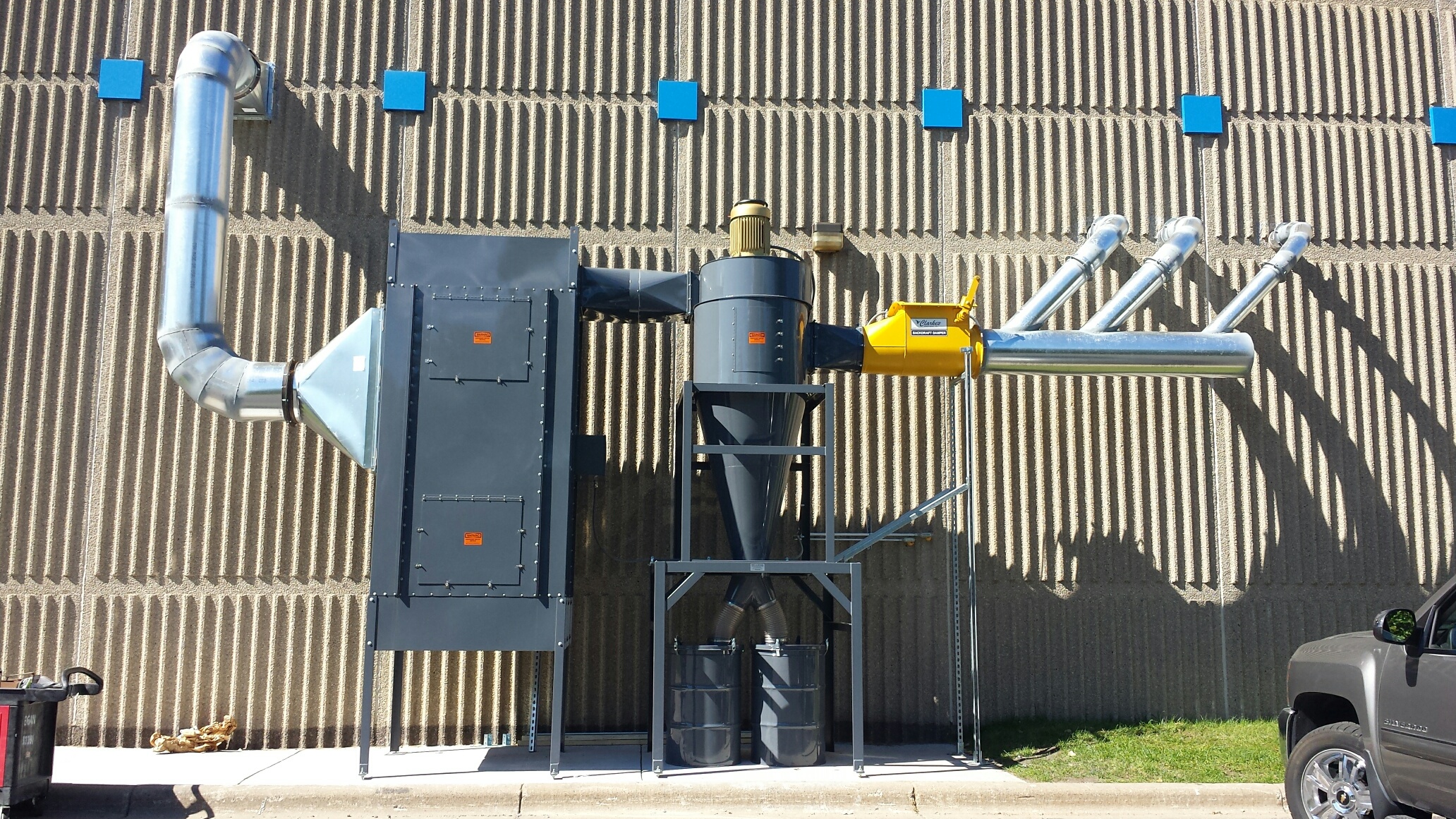

The most common and effective arrangement is a two-stage collection system with a pull-though cyclone dust collector and a fabric bag or tube-type after-filter. The cyclone dust collector pulls in contaminated air from the dust-producing source and removes larger coarse particles from the exhaust air stream using centrifugal force, allowing gravity to collect the contaminant into a storage container beneath the cyclone. The exhaust air is then sent to the second stage to filter out fine dust particles. For medium sized educational woodshops and industrial woodworking applications, an appropriately sized baghouse is recommended for filtering and collecting significant volumes of fine dust particles. In a small woodworking shop, a single large filter bag is adequate for the removal of the residual small particulate.

Benefits of a Cyclone

A cyclone dust collector is the most efficient dust collector for its cost. They require little or no maintenance, no filter changeout, and collect a majority of dust produced by common woodworking machinery and processes. The result is an exhaust stream with only fine particles remaining, creating a lighter dust load to be filtered out by the after-filter. A lighter dust load on the after-filter results in less frequent reconditioning, and longer fabric filter life of the bag or tubes contained in a baghouse. AGET systems are designed without a cartridge filter, which removes the requirement of compressed air for cleaning and reconditioning of the cartridge, lowering system installation and operational costs of supplying compressed air. Cartridge filters alone on a woodworking application are prone to quick plugging of the filter area, as large particles are not removed from the exhaust stream by a cyclone prior to the filtering stage. This issue also leads to higher operational costs, as the cartridge filters will need to be replaced often.

About AGET Manufacturing Co.

For many years, AGET has been a trusted partner and manufacturer of dust collection equipment for the woodworking industry. The efficient and effective design of our cyclone and after-filter components provide affordable equipment with low installation costs, as well as low on-going operating and maintenance costs. All of these features come together to provide a dust-free, healthy, and safe work environment that keeps woodshops of all sizes performing optimally for a long period of time.

For small or hobby woodshops, review our SC Series Pull-Through Cyclone brochure.

For educational or medium sized woodshops, review our School Woodshop brochure.

For industrial or large capacity woodworking applications, review our SN Series Pull-Through Cyclone and FT Series After-Filter or FH Series After-Filter brochures.

Contact Us

AGET Manufacturing designs and manufactures custom dust and mist collecting systems across the country. AGET’s products maximize efficiency and decrease operating costs, while helping to keep your people safe. Contact AGET or your local sales representative today for additional information or to request a quote:

Phone: (800) 832-2438

Email: sales@agetmfg.com